In a single step from the desktop to the microscale, Stanford University engineers have created the world’s first practical titanium-sapphire laser on a chip. The researchers have developed a chip-scale titanium-sapphire laser that is significantly smaller and less expensive than traditional models, making it suitable for broader applications in quantum optics, neuroscience and other fields. The new technology is expected to allow labs to house hundreds of powerful lasers on a single chip, powered by a simple green laser pointer.

Lasers made of titanium sapphire (Ti:sapphire) are considered to have “unparalleled” performance. They are indispensable in many fields, including advanced quantum optics, spectroscopy, and neuroscience. But this performance comes at a high price. Titanium sapphire lasers are on the order of a cubic foot in size. They are expensive, costing hundreds of thousands of dollars each. And they need other powerful lasers, costing $30,000 each, to give them enough energy to work.

Groundbreaking development in laser technology

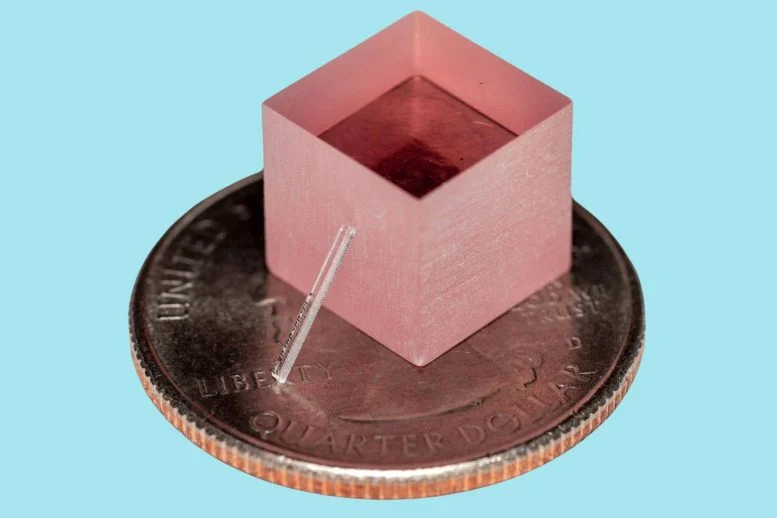

As a result, Ti:Sapphire lasers have never gained the widespread acceptance they deserve in the real world—until now. Researchers at Stanford University have made a quantum leap in scale, efficiency, and cost by creating a Ti:sapphire laser on a chip. The prototype is four times smaller (10,000 times) and three times cheaper (1,000 times) than any titanium-sapphire laser ever built.

Revolutionary miniaturization and cost reduction

“This is a complete departure from the old model,” said Jelena Vuchkovic, the Jensen Huang Professor of Global Leadership, professor of electrical engineering, and senior author of a paper introducing the chip-based Ti:sapphire laser published in the journal Cell. Nature. “Instead of one big, expensive laser, any lab will soon be able to have hundreds of these valuable lasers on a single chip. And you can feed them all with a green laser pointer.

“When you go to bench scale and manufacture something that can be manufactured on a chip at such a low cost, these powerful lasers become available for many different important applications,” said Joshua Young, a postdoctoral researcher in Vuchkovic’s lab and one of the first authors of this book. The research was conducted by research engineer Kasper Van Gasse and doctoral student Daniil M. Lukin, along with colleagues in Vuchkovic’s nanoscale and quantum photonics lab.

Technical advantages and mass production potential

From a technical standpoint, Ti:sapphire lasers are so valuable because they have the largest “gain bandwidth” of any laser crystal, Yang explained. Simply put, gain bandwidth means a wider range of colors a laser can produce compared to other lasers. Yang said they’re also super fast. A pulse of light is emitted in one quadrillionth of a second.

But Ti:sapphire lasers are also hard to come by. Even Vuchkovic’s lab, which conducts cutting-edge experiments in quantum optics, has only a few of these precious lasers to share. The new Ti:sapphire laser is mounted on a chip measuring in square millimeters. If researchers can mass-produce them on wafers, potentially thousands, perhaps tens of thousands, of titanium-sapphire lasers could be squeezed onto a disk that fits in the palm of a person’s hand.

“The chip is easy. It’s portable. It’s cheap and effective. It has no moving parts. And it can be mass-produced,” Yang said. “What’s not to love? Ti:sapphire democratizes lasers.”

Innovations in production

To create the new laser, the researchers started with a bulk titanium-sapphire layer on a silicon dioxide (SiO2) platform. 2 ) and it’s all on top of real sapphire glass. They then grind, etch and polish the Ti:sapphire down to an extremely thin layer, just a few hundred nanometers thick. In this thin layer, they create a rotating vortex of tiny protrusions. These protrusions are like fiber optic cables, directing the light around and around, increasing its intensity. In effect, this pattern is known as a waveguide.

“Mathematically, intensity is power divided by area. So if you keep the same power as a large-scale laser but reduce the area it focuses on, the intensity becomes unusual,” Yang says. “The small scale of our laser actually helps us make it more efficient.”

The remaining piece of the puzzle is a microscale heater that heats the light passing through the waveguides, allowing Vuchkovic’s team to change the wavelength of the emitted light, tuning the color of the light in the range of 700 to 1,000 nanometers from red to infrared.

Application and future prospects

What excites Vukovich, Young, and their colleagues most is the range of areas such a laser could affect. In quantum physics, a new laser is a cheap and practical solution that could significantly reduce the scale of modern quantum computers. In neuroscience, the researchers foresee an immediate application in optogenetics, a field that allows scientists to control neurons using light directed into the brain through a relatively bulky optical fiber. They say the tiny lasers could be integrated into more compact probes, opening up new experimental avenues. In ophthalmology, it could find new applications, as well as the Nobel Prize-winning chirping pulse amplification in laser surgery, or it could offer cheaper, more compact optical coherence tomography technologies used to assess the condition of the retina.

Next, the team is working to perfect their titanium-sapphire lasers at chip scale and mass-produce thousands of them simultaneously on wafers. Ian will complete his PhD this summer based on this research and is working to bring the technology to market.

“We can put thousands of lasers on a single 4-inch wafer,” Yang says. “Then the cost of a laser becomes almost zero. That’s very exciting.”

Source: Port Altele